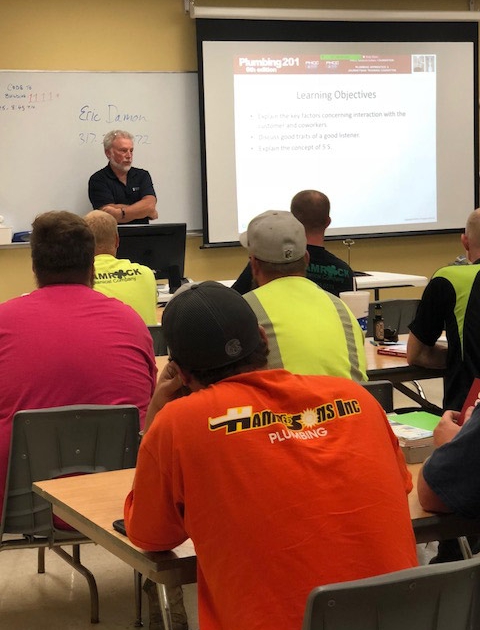

OUR APPRENTICESHIP PROGRAM

Mechanical Skills Plumbing Apprenticeship School program is ranked as one of the top plumbing school programs in the nation. Our educators have decades of experience teaching, working within the plumbing industry and as mentors through our journeyman portion of our apprenticeship program.

A four year curriculum, you will learn through both the classroom and hands-on within the plumbing industry.

Our classes are designed to take you from simple plumbing knowledge through in-depth plumbing design and implementation. Becoming a certified plumber will further your career whether as an employee or starting your own business.

We at Mechanical Skills strive to impart our depth of knowledge to further your lifetime of good plumbing.

Program Highlights

Throughout the apprenticeship program you will learn the most basic of plumbing skills, to in-depth knowledge of plumbing design, regulations that cover best plumbing practices and how to implement all you have learned.

Upon your completed registration and acceptance into Mechanical Skills Plumbing Apprenticeship program, we wish you the best of luck in your classes and in life itself.

OUR CURRICULUM

An apprentice may enroll in the program at any time during the year. The school year runs from August through May. If the apprentice enrolls after school is started they will be able to earn on the job training but their curriculum credit won’t start until the next school year. The enrollment allows for the application process to begin so that they can get their apprentice license and work under a licensed journeyman.

Credit for class is given in yearly increments of 144 hours. No partial credit is given if an entire year is not completed. If a student does not complete a year, no credit is given for that year and if re-enrolled the entire year would have to be taken over.

Two absences per semester for a total of four per year are allowed. There are no excused absences.

Year 1 classes.

1-0 Appendix B – Plumbing Code Definitions

1-1 Plumbing History, Codes, and Principles

1-2 Tools of the Plumbing Trade

1-3 First Aid and Safety

1-4 Basic Math for Plumbing

1-5 Water Supply, Water Sources, Waste Disposal, and Sewage Disposal

1-6 Gases in Plumbing Work

1-7 Mechanical Properties and Protection of Building Materials and Structures

1-8 Piping Materials Used in Plumbing Work

1-9 Joining Methods for DWV and Pressure Piping

1-10 Squares, Square Roots, and Basic Geometry

1-11 Plumbing Fixtures

1-12 Faucets and Related Devices

1-13 Valves

1-14 Building Plans, Drawings, and Scale Rulers

1-15 Sketching

Year 2 classes.

2-0 Indiana Plumbing Code – Chapter 2, Definitions

2-1 Piping Materials, Sources, and Distribution for Potable Water

2-2 Water Piping Sizing: Main and Branch Systems

2-3 Water Piping Sizing: Individual Run Systems

2-4 Cross-Connection Protection and Pipe Identification

2-4.1 Indiana Plumbing Code – Chapter 6, Water Supply

2-5 Codes and Hot Water

2-6 Water Heater Components, Replacement and Troubleshooting

2-7 Instantaneous Water Heaters & Water Heating Sizing

2-7.1 Indiana Plumbing Code – Chapter 5, Water Heaters

2-8 Mathematics Review and Linear Measure

2-9 Squares, Cubes, Square Roots and Cube Roots

2-10 Offsets

2-11 Shapes, Areas, Volumes, and Lead and Oakum Calculations

2-11.1 Indiana Plumbing Code, Chapter 3, Rules, General Regulations

2-12 Sewage Disposal Methods

2-13 Sewers

2-14 Drainage Fixture Units

2-15 Building Drains

2-16 Stacks

2-16.1 Indiana Plumbing Code, Chapter 7, Sanitary Drainage

2-16.2 Indiana Plumbing Code, Chapter 8, Indirect Waste Piping

2-17 Rough-In Sheets

2-18 Single Line Drawings: Residential & Commercial

2-19 Single Line Drawings: Industrial and Institutional

2-20 Details, Sections, and Exploded View Drawings

2-20.1 Indiana Plumbing Code, Chapter 4, Fixtures

2-21 Introduction to Welding, Gas Welding, and Safety

2-22 Soldering, Brazing, Cutting and Welding

2-23 Venting Plumbing Drainage Systems

2-24 Vent Piping: Hangers and Vent Types

2-24.1 Indiana Plumbing Code, Chapter 9, Venting

2-25 Sump Pumps, Sewage Pumps, and Sewage Ejectors

2-25.1 Indiana Plumbing Code, Chapter 11, Storm Drainage

2-26 Properties of Water

2-27 Plumbing Traps

2-27-1 Indiana Plumbing Code, Chapter 10, Traps & Interceptors

2-28 Air

2-29 Plastic Pipe and Fittings: Part I

2-30 Plastic Pipe and Fittings Part II

2-31 Hoisting and Rigging

2-32 Safety in Hoisting Operations

2-33 Ladders and Scaffolds

Year 3 classes.

3-1 Pre-Planning, Productivity and Profitability

3-2 Residential Fixtures and Appliances

3-3 Commercial, Industrial, and Institutional Fixtures and Appliances

3-4 Installation Methods

3-5 Fixture Fittings and Trim

3-6 Trim Installation

3-7 Blueprints and Specifications

3-8 Drawing Types, Floor Plans, and Site Plans

3-9 Structural, Plumbing, Electrical, HVAC, and Detail Plans

3-10 National Fuel Gas Code, Materials and Types of Fuel Gases

3-11 Fuel Gas Pipe Sizing

3-12 Fuel Gas Piping, Fittings, and Connections

3-13 Gas Appliances, Regulators, Meters and Appliance Controls

3-14 Fuel Gas Piping, Corrosion and Corrosion Protection

3-15 Vents for Category 1 Appliances

3-16 Gas Combustion and Controls

3-17 Study of Local Fuel Gas Codes

3-17.1 Indiana Fuel Gas Code, 2008 Edition (IFGC, 2006 Edition, 1st printing)

3-18 Level, Transit, Elevations and Grade

3-19 Builders Level

3-20 Builders Transit

3-21 Offsets

3-22 Tank Capacities Volume and Weight of Water

3-23 Ratios and Proportions

3-24 Storm Drainage and Sizing Storm Drains

3-25 Energy & Temperature, Piping Expansion, Heat Transfer Insulation, Humidity, and Condensation

3-26 Water Treatment

3-27 Heat Transfer in Water Heaters 0 Solar, Stratification, Multiple heaters and Recirculation

3-28 Basic Electricity, Electric Current and Electric Motors

3-29 Electric Circuits, Circuit Protection, and Electrical Safety

3-30 Electric Circuits Troubleshooting

3-31 Control Wiring

3-32 Indiana Contractors Business and Law Reference Manual, Chapter 2, Licensing Requirements

Year 4 classes.

4-1 Service Professionalism, Leaks, and Drainage Problems

4-2 Residential and Commercial Service and Repair

4-3 Industrial and Institutional Service and Repair

4-4 Water Piping Service and Repair

4-5 Drain, Waste, and Vent Piping Service and Repair

4-6 Fuel Gas Piping and Lead Product Service and Repair

4-7 Water Heater Service and Repair

4-8 Waste Stoppage Service and Repair

4-9 Water Hammer Service and Repair

4-10 Controls Troubleshooting

4-11 DWV Sizing Utilizing Blueprint Reading

4-12 Storm Drainage Utilizing Blueprint Reading

4-14 Fuel Gas Pipe Sizing Utilizing Blueprint Reading and Category I Vents

4-15 Indiana Contractors Business and Law Reference Manual, Chapter 3, Estimating and Bidding

When are classes held?

An apprentice may enroll in the program at any time during the year. The school year runs from August through May. If the apprentice enrolls after school is started they will be able to earn on the job training but their curriculum credit won’t start until the next school year. The enrollment allows for the application process to begin so that they can get their apprentice license and work under a licensed journeyman.

Credit for class is given in yearly increments of 144 hours. No partial credit is given if an entire year is not completed. If a student does not complete a year, no credit is given for that year and if re-enrolled the entire year would have to be taken over.

Two absences per semester for a total of four per year are allowed. There are no excused absences.

4-1 Service Professionalism, Leaks, and Drainage Problems

4-2 Residential and Commercial Service and Repair

4-3 Industrial and Institutional Service and Repair

4-4 Water Piping Service and Repair

4-5 Drain, Waste, and Vent Piping Service and Repair

4-6 Fuel Gas Piping and Lead Product Service and Repair

4-7 Water Heater Service and Repair

4-8 Waste Stoppage Service and Repair

4-9 Water Hammer Service and Repair

4-10 Controls Troubleshooting

4-11 DWV Sizing Utilizing Blueprint Reading

4-12 Storm Drainage Utilizing Blueprint Reading

4-14 Fuel Gas Pipe Sizing Utilizing Blueprint Reading and Category I Vents

4-15 Indiana Contractors Business and Law Reference Manual, Chapter 3, Estimating and Bidding

GREAT FOR YOU

Our classes are scheduled with you in mind.

Held one night per week, starting at 6:00pm, with classes on Monday, Tuesdays, Wednesdays and Thursdays for a maximum of 3 hours per week.

Mechanical Skills holds 34 classes in a school year, which comprises two semesters made up of two quarters per semester.

On the Job Training (OJT) hours are recorded monthly with signature by an approved journeyman and turned into your instructor for credit.

O.A. REQUIREMENTS

These are the requirements for a plumbing apprentice for completion of the Plumbing Apprenticeship Program, as set by The U.S. Department of Labor, Office of Apprenticeship.

7,600 Hours of On-the-Job Training

1,900 per year for a four-year period

576 Hours of School Related Training

144 hours per year for a four-year period

Each employer sponsor is responsible for enrolling the apprentice into the program and making it possible for the apprentice to acquire on the job training hours and allowing the opportunity for the apprentice to attend classes.

WHAT IS O.A.?

The U.S. Department of Labor, Office of Apprenticeship (formerly known as BAT).

Mechanical Skills, Inc. is an approved Office of Apprenticeship (O.A.) plumbing apprenticeship training program.

Contact Mechanical Skills Plumbing Apprenticeship School today to register and start your path towards becoming an approved plumber.